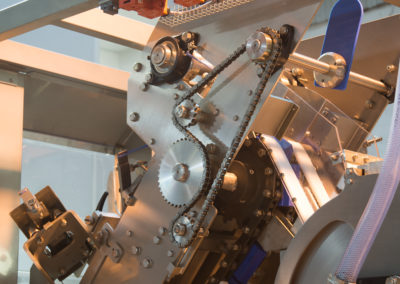

Large Onion Peeling Machine

The Large Onion Peeling Machine from M&P Engineering tops, tails and peels onions of 45mm to 115mm diameter using self adjusting floating knife assemblies over a range of up to 25mm on any one setting. It then slits the onion horizontally from top to tail, the depth of slit is determined by onion quality and grade. The machine finally removes the skin using compressed air providing an end product of optimum appearance. This video gives an introduction to the Onion Peeling Machine and explains how it works. If you cannot access YouTube, there is a high quality mp4 video here and here.

Features & Benefits

The large onion system features:

- Dry peeling process

- Continuous operation

- Automatic pick-up of onions from hopper

- No change parts required when varying onion size

- Variable Speed up to 110 carriers/minute (Normal operating speed 90 carriers/minute)

- Labour requirements of 3 or 4 depending on product quality

- Simple mechanism, using a tried and testing mechanical design

- Raw material input rate approximately 750kg per hour using onions 75mm to 90mm diameter, 600kg per hour using onions 60mm to 80mm diameter

Giving these benefits:

- No water usage, no waste slurry to deal with, product remains dry.

- Simple to operate.

- Low labour requirement.

- No batch unloading process leaving peeled onions undamaged.

- Can work with wide range of product size and quality.

- No change over time between different products.

- High volume, high quality output.

- Simple to clean and maintain.